The Need for Greener Floor Care

The floor care industry has been undergoing a significant transformation as manufacturers and consumers are increasingly demanding more environmentally preferred solutions. The relatively slow adoption of eco-friendly raw materials into floor care is finally picking up with improved innovation in chemistry designed for high-performance floor finishes. There are many ways manufacturers can meet this demand, including incorporating zinc-free polymers, additives with no intentionally added PFAS, and natural surfactants and wax additives.

Why is it important to focus on "green" chemistry?

The North American floor care market has been growing steadily, fueled by the increase in residential new construction/home renovations, construction of new healthcare facilities, and commercial construction.1 The current North American interior finish market is valued at around $3.5 billion (2023) with projected growth of 6.12% CAGR to $5.9 billion within the next 7 years.2

With the projected growth comes consumer demand for more sustainable options. There has been a noticeable shift in preference for products that are biodegradable, non-toxic, and “free” of harmful forever chemicals. Regulatory bodies are also involved in this shift, as government agencies like the U.S. EPA are putting more stringent regulations on certain raw materials, including per- and polyfluoroalkyl substances (PFAS) and zinc. Because of this change, floor finish formulators like Barentz have innovated and supported the development of raw materials that can help product formulators meet demand for high-performance, sustainable floor finishes.

What are the solutions for formulators like you?

- Zinc-free polymers: Transitioning from traditional to zinc-free polymers helps manufacturers reduce the risk of heavy metal pollution in local water systems. Additionally, many floor finishes made with zinc-free polymers show lower levels of volatile organic compounds (VOCs) than traditional polymers. Zinc-free polymers also offer good durability, removability, gloss, and other highly sought after performance characteristics.

- Naturally-sourced additives: Naturally-sourced wax additives and biobased surfactants have the potential to improve the biodegradability, toxicity ratings, and overall performance of floor finishes. Incorporating these raw materials into floor finish formulations can aid in certain “Green Certification” processes.

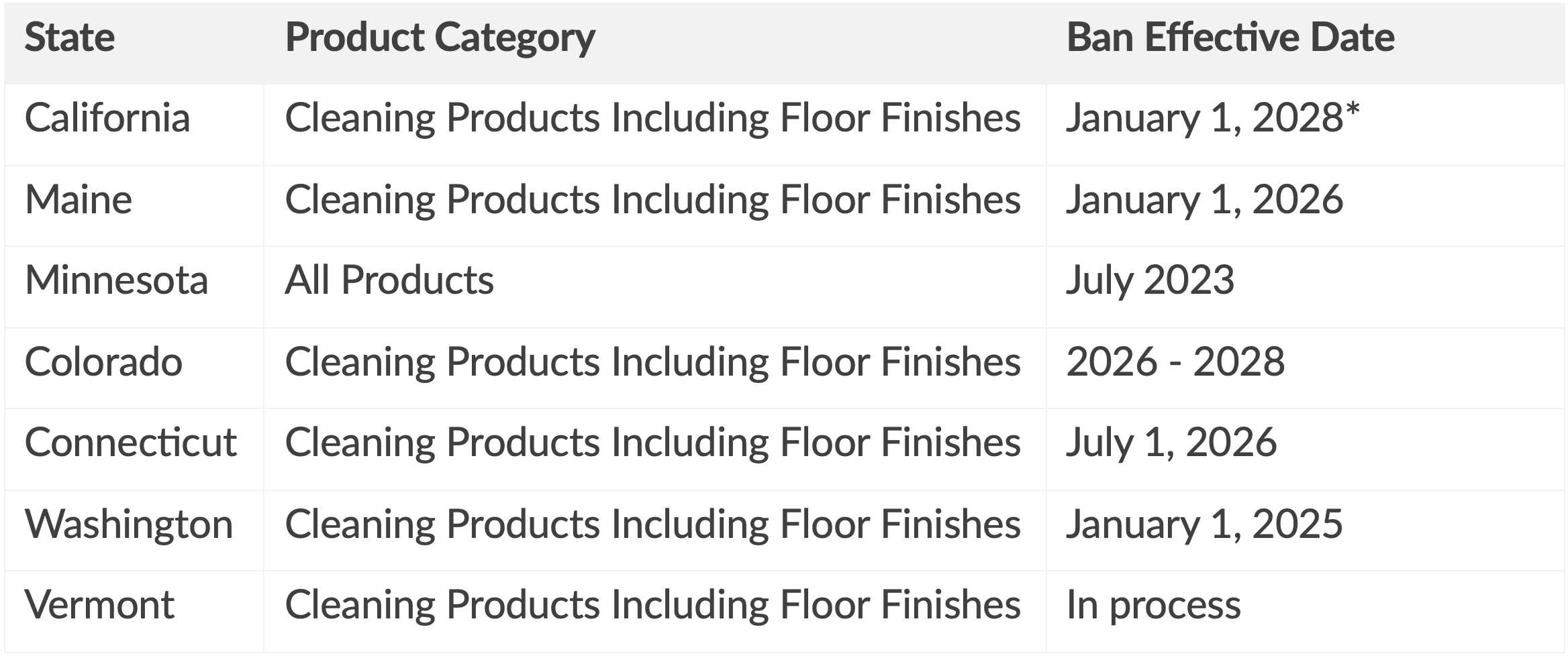

- Wetting aids made with no intentionally added PFAS: PFAS and forever chemicals are a hot topic these days. Certain U.S. states created guidelines for the removal of intentionally added PFAS in floor finishes (and other cleaning compounds).2