Experts in Excipients

MEGGLE

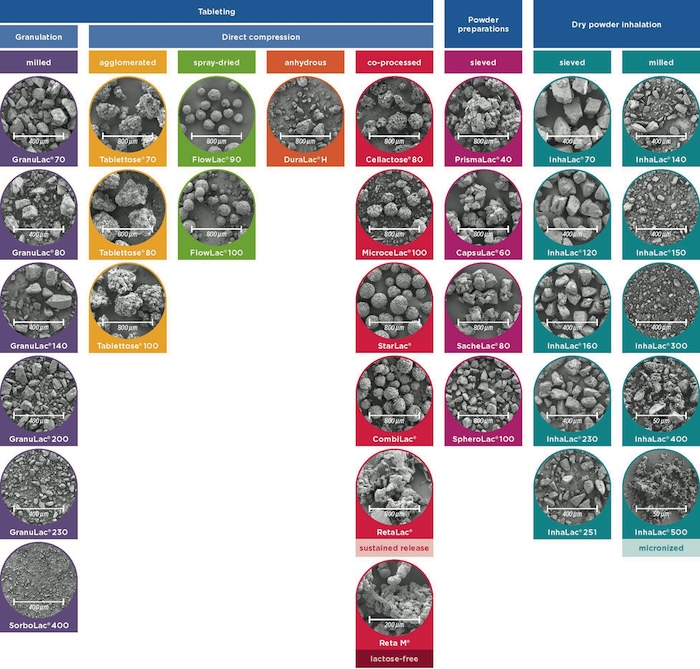

MEGGLE Excipients produces high-quality pharmaceutical excipients tailored for various formulations, including direct compression, granulation, capsules, sachets, powder blends, and dry powder inhalation. MEGGLE has established a prominent position within the global excipient market by leveraging a comprehensive product portfolio and innovative solutions. With production facilities in Wasserburg am Inn, Germany and Le Sueur, Minnesota, MEGGLE serves the requirements of the North American market, and it is prepared to meet customer expectations

View Products